by Mary Caperton Morton Thursday, January 5, 2012

Humpback whales flout conventional hydrodynamics by sporting 10 to 11 tubercle bumps along the front edge of their flippers. Christopher M. Keane

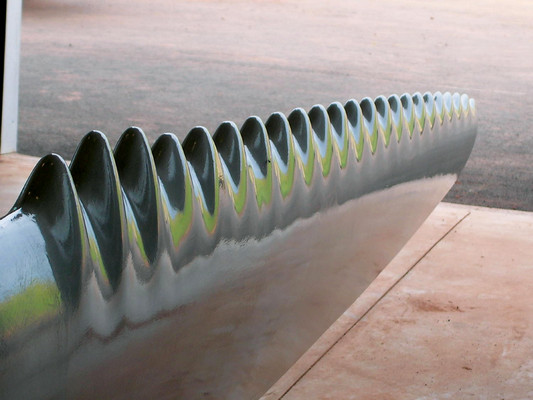

A Whalepower 'Tubercle Technology' turbine blade. Whalepower

According to conventional wisdom, things that need to move efficiently through air or water should be sleek and streamlined. Dolphins, jets and Olympic swimmers stick to this rule, but humpback whales, with their massive knobby-edged flippers, buck the trend.

Flipper bumps, called tubercles, are unique to humpbacks. Tubercles were a hydrodynamic anomaly until biologist Frank Fish, from West Chester University in Pennsylvania, stuck a four-meter-long flipper collected from a deceased beached whale in a wind tunnel and discovered that humpbacks are on to something: The flipper was exceedingly aerodynamic.

Humpbacks are the most maneuverable of the large whales, Fish says. Their spectacular breeches make them a favorite among whale watchers and their bulk-defying underwater agility enables them to catch bigger, faster prey than other whales. It turns out those funny bumps are the key to the 30-ton whale’s acrobatics skills, Fish and colleagues suggested in Integrative and Comparative Biology in May. The tubercles channel water over the flipper in such a way as to prevent stall — the loss of forward movement — and allow the whales to turn deftly and move efficiently underwater, Fish says.

Fish’s discovery is changing the way engineers think about aerodynamic design. Whalepower, a Toronto-based company, is redesigning wind turbine blades with a humpback-inspired bumpy leading edge. The new “Tubercle Technology” blades produce more energy more efficiently than conventional smooth blades. “The energy production from these blades is extraordinary,” says Stephen Dewar, head of research and development. Although the bumpy blades are still in the testing phase, Whalepower hopes to begin production within the next year. At least 10 wind power companies have already shown interest in the new blades, with good reason. Dewar says, “These might prove to be the most efficient turbine blades ever made.”

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.