by Paul D. Lowman, Patrick T. Taylor and M. Bruce Milam Thursday, January 5, 2012

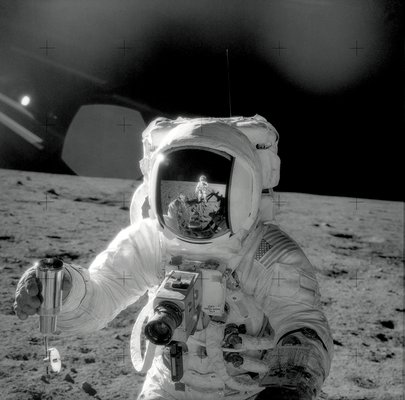

An Apollo 16 astronaut drills in simulated lunar soil during a training exercise before a moon landing. NASA Kennedy Space Center

Apollo astronauts brought lunar rocks and soil back to Earth for analysis. Johnson Space Center

The Luck Stone Corporation of Virginia supplied NASA scientists with diabase samples for their work. Luck Stone Corporation

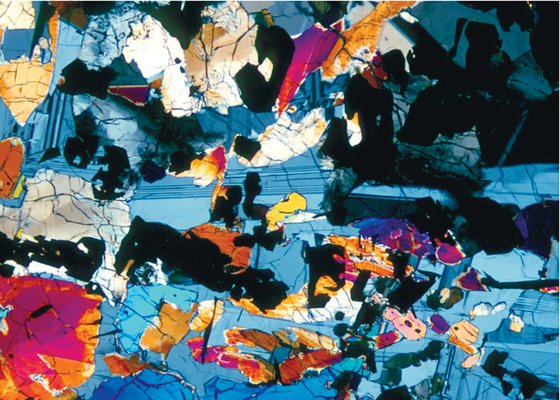

Photomicrograph of a thin section of lunar basalt under cross-polarized light. The basalt was collected by Apollo 17 astronauts. Kurt Hollecher, Union College

Researchers from NASA and Honeybee Robotics filled a 10-meter-tall pipe with crushed diabase from Virginia to simulate drilling on the moon. It worked. Courtesy of Kris Zacny and Patrick Fink, Honeybee Robotics

The Lunar Roving Vehicle was designed to transport astronauts and materials on the moon during the Apollo 15 (shown here), Apollo 16 and Apollo 17 missions in 1971 and 1972. NASA Marshall Space Flight Center

NASA's K-10 rover has been tested at Haughton Crater in northern Canada and other locations to see if it's suitable for lunar travel. At the front of the rover is a geotechnical tool that assesses soil strength. Courtesy of Kris Zacny and Patrick Fink, Honeybee Robotics

Lunar exploration is once again in full swing. Japan’s Kaguya and India’s Chandrayaan-1 satellites are currently in orbit around the moon. China’s Chang’e spacecraft, after a successful mission, has been intentionally crashed on the moon. And the United States’ Lunar Reconnaissance Orbiter is preparing to launch. These are all unmanned missions; humans haven’t been to the moon in more than 30 years. But we will probably return in the next decade, and when we do, we hope to dig even deeper to uncover the moon’s secrets.

What we know of the lunar regolith — the loose soil and rock blanketing the moon’s bedrock — we learned from the Apollo missions. But we have many lingering questions about the moon’s composition, its internal structure (such as whether it has a core and what size it is), its age and its origin. A recent National Research Council report on lunar exploration recommends that all of these questions be given high priority. To answer them, we’ll need to continue the geophysical studies successfully carried out during the Apollo missions, including conducting seismology and heat-flow measurements — but now with the advantage of 21st century technology.

The Apollo missions also taught us some of the challenges that astronauts will face in conducting these investigations, particularly when it comes to drilling into the lunar soil. So to better prepare astronauts for what they might encounter in a future mission, we must first better understand the regolith. Fortunately, it’s possible to learn something about the moon’s surface here on Earth: As it turns out, moon-like rocks on Earth are not that hard to find. And they are already teaching us a lot about how to drill through lunar regolith to reach a depth where we can figure out more about the moon.

Starting with Apollo 15 in 1971, astronauts drilled 1.4- and 1.0-meter-deep shallow holes in the lunar regolith. The drilling proved difficult, however, due in part to a faulty drill stem design. The lunar regolith was also difficult to drill because, having been formed and shaken by billions of years of impact and having no air as a lubricant, the soil becomes much denser a meter or so down. By the Apollo 17 mission in 1972, the drill stem flaws were corrected and astronauts were able to drill more than two meters deep. Still, with the moon’s regolith thought to be tens of meters deep or more, two meters wasn’t nearly deep enough to get a solid geologic picture of the moon’s interior.

In fact, measurements of heat flow — which tell us about the moon’s internal composition — will require holes at least five meters deep, to distinguish between daily and longer-term thermal variations. To figure out what tools future astronauts will need to dig through the lunar regolith, we began a study of new drilling techniques last year, one that would include realistic drilling experiments.

Needless to say, actual lunar soil is far too valuable to use for such work. The lunar maria (the volcanic rocks making up the dark portions of the Earth-facing surface of the moon) are basalt, the most common igneous rock in the solar system, making up most of Earth’s oceanic crust, much of the Martian crust and even some asteroids. Lunar “simulants” made from analogous terrestrial igneous rocks — such as volcanic rock from Arizona and Minnesota — have been used for decades, but none was available in large enough quantities for our study. So we searched geological maps and literature to see if any local rocks could be used. Fortunately, from previous fieldwork, we found a candidate site in Leesburg in Loudoun County, Va., only an hour’s drive from our offices at NASA Goddard Space Flight Center in Maryland — not precisely next door, but considerably closer than Mare Imbrium, where Apollo 15 landed.

This lunar simulant candidate is a 160-million-year-old diabase in the Culpeper Basin, a rift valley in Northern Virginia. Diabase — a type of basalt — is common in the eastern United States, forming the Palisades and Watchung Mountains of New Jersey and occurring in many parts of the Appalachian chain. It occurs in extensional (rifting-related) structures like the Culpeper Basin, a feature thought to be related to the Mesozoic opening of the Atlantic some 200 million years ago.

Hoping the diabase would suffice but needing to learn more about it, we toured a diabase quarry in Leesburg, owned by the Luck Stone Corporation. The geology turned out to be surprisingly complex, with transverse folds, several major faults and considerable fault-controlled hydrothermal alteration. On the moon, because there is no water or free oxygen, you would not find such alteration. So to find diabase samples that would match as closely as possible to the lunar regolith, we collected hand specimens of the diabase well away from any alteration zones.

We took these samples back to the lab and examined them under a microscope to see just how similar they are to lunar basaltic rocks. A comparison with lunar mare basalts showed the Leesburg diabase to be amazingly similar to the Apollo samples.

The Leesburg rock is composed chiefly of the minerals clinopyroxene and plagioclase, with small amounts of opaque minerals (probably titanium-rich magnetite), quartz and biotite. And like lunar basalts, which are completely water-free, the diabase had no hydroxyl-bearing minerals, except for minor biotite. This was the first similarity we found between our diabase and lunar basalts. A second similarity was that both the lunar rocks and the diabase contained “diallage,” a type of clinopyroxene that appears as thin, parallel layers. In 1941, the late Harry Hess demonstrated that diallage results from “subsolidus exsolution,” a gradual process in which a solid mineral that was once homogeneous chemically separates into different minerals as it cools. Further examination using tools such as scanning electron microscopy revealed that the Leesburg and moon samples also share similar grain size and grain shape.

There are of course major differences. Lunar basalts are both water-free and oxygen-free, and also therefore have no ferric iron, whereas the magma from which the Leesburg diabase crystallized clearly had normal water content, as shown by the fault-controlled alteration zones. Furthermore, the regolith is largely composed of glassy fragments, called agglutinates, which formed during impact events, as Larry Taylor, an authority on lunar simulants at the University of Tennessee in Knoxville, pointed out to us. Such agglutinates can form only on airless bodies such as the moon, and must be produced artificially to make realistic simulants.

Still, we determined that the Leesburg rock was similar enough in physical properties to lunar rock — based on its mineralogy, grain size and other similarities — to test our drilling methods. It was also readily available and inexpensive, and the Luck Stone Corporation provided us with 20 tons of crushed diabase for our experiments.

For the drilling tests, we teamed with some folks who are no strangers to digging in the dirt on alien worlds: the Honeybee Robotics Spacecraft Mechanisms Corporation, a company with extensive experience in spacecraft mechanisms. Honeybee built the scraper used by the Phoenix Mars Lander to dig up and collect samples of the Martian soil and ice. The Honeybee staff, led by Kris Zacny, had also been doing moon-drilling experiments with small samples of a new simulant made from Arizona volcanic rock.

In comparison to the many tests on the suitability of diabase, the testing of our drilling equipment was pretty straightforward. The engineer among our Goddard team, Bruce Milam, who has heavy-equipment operating experience from working in the West Virginia coal mines, erected a 10-meter-long iron pipe, which we filled with our crushed diabase powder and then packed down to simulate the denser lunar regolith. We set it up on Milam’s farm in Bowie, Md., and started the drilling. This provided a preliminary feasibility test for drilling techniques and the new drilling equipment developed by Honeybee for the moon. The results were highly encouraging: Unlike previous drilling efforts, we reached a depth of 10 meters with no major problems.

Of course, these experiments must be viewed cautiously; even after packing down our simulant “soil,” the moon’s hard vacuum, low gravity and billions of years of history meant that our “lunar regolith” was nowhere near as compact as the real thing. (We hope that using an Earth-based vacuum chamber will make future drilling tests more like the moon.) Nonetheless, these first experiments will help us be better prepared to drill on the moon — and to resume the geological research started more than three decades ago.

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.