by Bridget Mintz Testa Thursday, January 5, 2012

At left, one of the original mine pits at Syncrude's Mildred Lake oil sands mine in Alberta, Canada. At right, the same area after reclamation. Both: Courtesy of Syncrude Canada Ltd.

Before: One of the original mine pits at Syncrude's Mildred Lake oil sands mine. Courtesy of Syncrude Canada Ltd.

Gateway Hill, Syncrude's certified reclaimed area, was planted in the early 1980s. Courtesy of Syncrude Canada Ltd.

And after: Syncrude's reclaimed Mildred Lake oil sands mine, in Alberta, Canada. Courtesy of Syncrude Canada Ltd.

An area in the process of being reclaimed. Courtesy of Syncrude Canada Ltd.

Bill's Lake is another Syncrude reclamation site. Reclamation began here in the 1990s. Courtesy of Syncrude Canada Ltd.

Syncrude's water cap tailings test ponds, where the company tests plants to determine which eliminate pollutants and set up the best ecosystem. Courtesy of Syncrude Canada Ltd.

Syncrude researcher taking a sample of groundwater in one of the company's reclamation areas. Courtesy of Syncrude Canada Ltd.

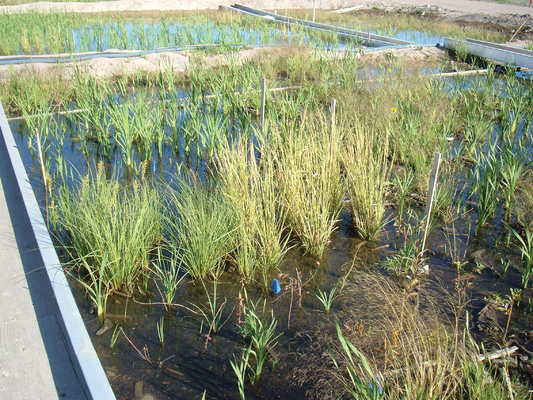

Researchers grow many different plants on more than two dozen test plots to determine what to plant in a wetland in a reclaimed area. Courtesy of Syncrude Canada Ltd.

Hiking through the 104-hectare parcel of land known as Gateway Hill in the Canadian province of Alberta, you pass through a boreal forest of aspens, spruce and jackpine, possibly detouring around one or more wetlands. You might catch glimpses of foxes, rabbits, deer, coyotes and various species of birds. You could picnic among the trees or stretch out for a nap beneath one, secure in its shade. You would almost certainly imagine that this ecosystem looked much the same 20 or 30 years ago — and you would be wrong.

In 1983, what is now Gateway Hill was a defunct section of a surface mine in the Athabasca Oil Sands Deposit, which lies just northeast of the center of Alberta. If you had hiked the area then, you would have seen what resembled a moonscape: Nearly devoid of life, the area was marked by large, deep gouges in blackened ground, dug to get to the unconventional oil reservoirs hidden far beneath the surface. It was not a pretty sight.

But that was then. Today, Gateway Hill, restored by Syncrude, is the only location that Alberta Environment — the provincial government’s overseer of oil sands reclamation — has certified to be equivalent to its pre-mine condition, but many other oil sands surface mining reclamation projects are under way. At other sites where active mining is no longer occurring, Syncrude is building a lake and a type of wetland known as a fen. Other oil sands mining companies have their own projects as well.

Reclaiming the oil sands surface mines is not a matter of a project here and another one there. By law, after the oil is extracted, each section of a mining company’s lease must be returned to a state equivalent to what it was in before a tree was cut or the first shovel hit the dirt. It does not have to be identical, but it does have to represent the boreal ecosystem. The mining companies are required to make the mines and everything associated with them disappear, so that you’d never know a mine was there. The goal is to achieve, as much as is possible, the same natural ecosystem that existed before anyone ever uttered the phrase “oil sands.”

If you walk along the bank of the Athabasca River in Alberta and pick up a handful of the dark sand, it feels oily. That’s not due to pollution; the oil is naturally bound to the sand.

Indeed, Alberta’s crude oil doesn’t feel like a liquid at all. It feels and flows like asphalt or molasses, and people in the industry often refer to it as tar. The highly viscous black stuff is known as “bitumen.” The bitumen in oil sands is a thin coating wrapped around a layer of water that envelops a grain of sand. Separating that thin coating of bitumen from the sand and water is the primary objective of oil sands mining and extraction.

Production-quality oil sands are not found on the surface. Those accessible by surface mining are found about 50 to 75 meters under the surface in large underground deposits. To reach deposits deeper than that, “in situ,” underground-only methods must be used. The deposits in the Athabasca region are known as the McMurray Formation, a Lower Cretaceous oil-bearing quartz sandstone, thought to have formed 130 million years ago. The deposit lies below marine clays of the Clearwater Formation and above Devonian limestone of the Beaverhill Lake Group.

To get to the oil sands, mining companies remove all the timber at a mining site, remove the top meter or two of topsoil, and clear away the “overburden” — the mix of sand and clay that lies directly atop the oil sands. Then extraction begins.

Producing the oil is a lengthy process in which huge trucks and shovels dig up oil sands in big chunks. Those chunks get crushed, become a slurry with the addition of water and are piped to an extraction facility. Bitumen separation begins in the pipeline and finishes at the extraction facility, where hot water and soapy catalysts wash the bitumen free of the sand and water. This separation is the sole purpose of the entire extraction process.

Process water, sand and clay are piped to tailing ponds. For some of the oil sands mining companies, the bitumen then travels to an “upgrader,” a refinery where the bitumen, which is still thick and viscous, is converted into a higher-quality crude oil that can more readily be sold on the global market.

Last year, Alberta produced about 1.3 million barrels of oil a day from oil sands. There’s plenty more. The province has 170 billion barrels of proven, recoverable oil reserves in the form of the oil sands, second only to Saudi Arabia. Those reserves are retrievable by current methods, but another 315 billion barrels may be recovered from the oil sands by advanced technologies.

But all of that oil comes at a cost to the environment. Although in-situ operations do disturb the surface, that disturbance is much less than the impact of surface mining, which scrapes everything away to get to the prize. The surface covering the three big oil sands deposits in Alberta totals 142,200 square kilometers, and of that, mining has disturbed about 4 percent. Sixty-five square kilometers have been reclaimed, and Gateway Hill makes up only a tiny fraction of that.

So far, of the 14 or so energy companies surface mining the oil sands, Syncrude is the only company that has applied for a reclamation certificate, says Brett Purdy, a reclamation specialist at Alberta Environment. Gateway Hill “was an area right at the edge of their lease, and it was easy to return to the government. There are areas with Syncrude and Suncor [another oil sands mining company] that are in similar shape, but they are right in the middle of their leases,” Purdy says. How land returned to the government in the middle of an oil sands lease would be managed is unclear.

Turning desolate areas into pieces of what will one day be a large-scale boreal ecosystem presents enormous challenges. Disturbed land, mine tailings and water used in extraction and upgrading must all be reclaimed as part of that future ecosystem.

Gateway Hill is located on the southeastern corner of Syncrude’s oil sands lease, between East Mine and Ruth Lake. Its reclamation began in 1983, and it provided many lessons in building the proper soil foundation to grow a healthy forest.

The first step was to emplace a thick layer of overburden on the mine’s surface, says Ron Lewko, Syncrude’s team leader for environmental research. In this region, the overburden is composed of clay, sand and water that are naturally high in sodium sulfate, a salt. Salty soils are normally not good for plants.

And yet, boreal forests were growing on this overburden before mining operations began. They grow just fine as long as the saline soil is out of the reach of the plants, at least 50 centimeters to a meter beneath the surface, says Ellen Macdonald, a professor in forest ecology and plant diversity at the University of Alberta in Edmonton. “The systems are resilient,” she says. “You just need to boost them above that saline layer.”

Furthermore, Lewko says, the clay in the overburden slows water penetration, which slows the release of salts from the clay into vegetation. “Vegetation can grow fairly successfully because the salt release from the clay overburden is slow, and the precipitation dilutes the salt so it doesn’t inhibit the vegetation from growing,” he says. Despite those factors, Syncrude monitors the rate and quantity of the slow flushing of salt to the surface from the overburden in Gateway Hill to see if it and the vegetation continue to behave as expected.

Once the overburden was laid down, Syncrude next emplaced a “forest layer,” which was a mixture of overburden, peat and forest floor material that contained nutrients but no living matter. This was the standard practice in the industry until about 10 years ago, Macdonald says, when experience showed that the quality of this particular mixture deteriorated over time. Syncrude did not know this at the time it began Gateway Hill. Now ecologists realize it is necessary to include living material in this mixture. This forest layer should consist of a 35-centimeter- to 1-meter-thick layer of soil that has seed sources, roots, rhizomes and other living material, she says. The top 50 centimeters in particular is the most valuable part of the entire reclamation process.

Another lesson learned along the way involves the use of peat to create Albertan boreal forests. Peat is found in abundance in the area’s wetlands, but it’s not the kind of surface organic material that is naturally present in the region’s highland forests, says Sylvie Quideau, associate professor and associate chair for research in the Department of Renewable Resources at the University of Alberta. Yet there was little choice. “They only have so much of that [forest floor] material, so they’re trying to see how best to use it,” Quideau says.

Today, Syncrude and the oil sands mining industry are well aware of the benefits of those top 50 centimeters of forest material and carefully salvage or store it when opening up a new mining operation. “When we salvage it, we use it right away on top of the overburden at another reclamation site,” Lewko says. “If there is no immediate site, we store it away, outside of the mining area. It needs to be a short distance away, because if you move dirt a lot, it costs more. We pile it up in the open.” But they need to use it quickly, because by year two or three of storing it in the open, the live material dies, Macdonald says.

In light of these challenges, Quideau is working on developing the right kind of soil for reclaiming oil sands mine areas and turning them into forests. “Soils are complex,” she says. “Soils take time to develop, and we’re trying to see how to kick-start the biogeochemical processes involved in building sustainable soils.” To help understand these processes, Quideau is tracking the nitrogen flux between plants and the soil, because it’s the most limiting nutrient in boreal forests.

Quideau is also studying how reclaimed oil sands areas compare to natural sites where the soils and ecosystems are recovering from different types of disturbances like fires. “We’re looking at the ecosystems when they’re just burned, 10 years after the fire, 20 years afterward, and so forth,” she says. “We’re trying to see if the reclaimed areas will function as young ecosystems — if they’ll mimic what Mother Nature has done.”

The bitumen extraction process produces a lot of “leftovers,” including little platelets of clay, tiny amounts of hydrocarbons such as bitumen and naptha, coarse sand particles and clarified process water. These leftovers are sent to tailing ponds where they separate into four discrete layers: bitumen, naptha and napthenic acids on the surface; then a layer of clarified process water; then the clay platelets; and finally the sand at the bottom. The water can be pumped out and returned to the extraction process, leaving the rest of the material to be reclaimed.

The clay platelets, or soft tailings, are a difficult material to reclaim. “It has a yogurt consistency, and it isn’t thick enough or solid enough to walk on,” Lewko says. “We have been researching this problem [of reclaiming soft tailings] for more than 20 years.” One response to the challenge is to fill a pit with soft tailings and cap it with water to create a lake that will, over time, develop a clay bed as the soft tailings separate out and drift down.

At West Mine Pit in its Mildred Lake Lease, Syncrude is creating such a lake. This is not a re-creation of a lake that used to be there; it’s an effort to reclaim the soft tailings in a beneficial fashion. The lake, known as Base Mine Lake, will be about 7 square kilometers in size and more than 60 meters deep, serving as a full-scale testing ground for this soft-tailings water-capping process.In 1989, the lake-building project started with seven test ponds. Syncrude poured in water from several sources: freshwater from the Athabasca River, extraction process water, runoff from snow and rain, and mixtures of the three. Every test pond supported vegetation and aquatic life, including insects, frogs and fish. In 1993, they increased the size of the experiment.

Now Syncrude is filling Base Mine Lake with tailing pond water in which the soft clay platelets are suspended. “The water ... in the mining process has been constantly reused in a closed loop through the tailing ponds,” Lewko says. “[The water has] been exposed to oil sands and clay, some of which is a marine-based clay from an ancient sea that covered the area about 100 million years ago. That old marine-based clay contains a lot of salt, and the mining water that has been exposed to [the clay] is therefore also very salty. [The mining water] also contains napthenic acid, naptha and bitumen — hydrocarbons that can be toxic to aquatic life. [It] can’t simply be released into the environment.” The water must be cleaned up first, and Syncrude and the Alberta government are in early stages of developing water-quality guidelines.

The tailing pond water isn’t entirely toxic. It also contains beneficial microorganisms, according to Lewko. Along with air and sunlight, those microorganisms weather and break down the toxins, a bioremediation process that happens naturally in tailing ponds.

Salt can be removed from the water and clay, but it is an energy-intensive process that concentrates the salts into a sludge that requires disposal. But the salt should not need to be removed anyway. The salt will be so diluted by the lake’s large volume and natural inflow and outflow water that it won’t be harmful to aquatic life, Lewko says.

In addition to the tailing pond water, precipitation and runoff are also filling the lake. There’s even a freshwater flow-through back to Syncrude’s water-recycling operation. In 2012, Syncrude will stop filling the lake.

Syncrude researchers think they need at least 15 years of monitoring “to make absolutely sure the lake is doing what it’s supposed to be doing,” Lewko says. “Land reclamation takes at least 15 years of monitoring, and it takes 15 years for a natural forest to grow,” he says. If the lake is a success, by the mid-2020s, people may be fishing there. Even if fishermen aren’t catching prize-winning lake trout by then, Syncrude says it will know whether or not the lake behaves like natural lakes in the region.

Northern Alberta’s large boreal ecosystems are mosaics, comprising about

60 percent forest and 40 percent wetlands. In 2004, Syncrude decided to

experiment with creating a wetland to further its efforts to reclaim its

oil sands lease and return the land to its pre-mine state.

In the natural boreal ecosystem, peat-forming wetlands known as bogs and

fens are abundant. “Bogs receive all nutrients and water from

precipitation, whereas fens receive nutrients and water both from

precipitation and runoff,” says Dale Vitt, professor and chair of the

department of plant biology at Southern Illinois University in

Carbondale. “Fens develop into bogs over time, and fens form when the

water table rises enough to wet the surface mineral soil.”

Once this happens, mosses and other plants invade the fen, and eventually peat forms. Peat is the organic material that forms when mosses, particularly Sphagnum mosses, decompose in water. Peat formation from plant decomposition is slow — on the order of thousands of years — but the peat builds up because its production is faster than the rate of its own decomposition.

To build a boreal wetland, “one should imitate nature by placing water on mineral soils and letting the peat grow,” Vitt says. “The water level must remain stable to build peat; it can’t fluctuate.” Because the terrain where Syncrude plans to build its fen is flat, the company is resculpting the landscape into a hilly bowl. The wetland will sit at the bottom of the bowl, where it will be open to precipitation and where the hills will provide runoff and protect the developing fen. The entire watershed will encompass about 46 hectares, of which approximately 15 hectares will be fen.

The available soil for the fen contains a lot of sodium, which most plants, especially mosses, don’t tolerate well. Vitt is therefore trying to figure out what kind of plants can be used to establish the fens. “They must grow in the mineral tailings and in peat,” he says. “They must be big enough to produce a microclimate so other plants can grow.”

They will also have to tolerate calcium. Engineers hope that the sodium in the starting soil will eventually leave the system by dissolving in the fen’s water. Through the various sources of water, the fen will fill to the top. Water will then trickle away, carrying the sodium with it and leaving the fen at its previous level. If that happens, however, calcium will largely replace the sodium, and the plants must also be able to tolerate it. So far now, Vitt is left with many questions about the types of plants to use and whether they’ll come from seedlings grown in a greenhouse or from seeds sown in the wet soil. Fertility of the seeds is also a question mark.

To help answer these questions, in fall 2008, Syncrude established more than two dozen 20-meter-by-30-meter U-shaped plots on the east side and roughly in the center of Syncrude’s lease. Last winter, Syncrude researchers filled half of the plots with living, but initially frozen, peat that was cut from a natural peatland. As temperatures rose in the spring, the peat thawed. Last spring, they planted the other 14 plots with various plants and different types and depths of peat to evaluate growth.

Based on the results of these experiments to date, Vitt thinks the plants for the fen will include grass-like sedges, flowering perennials known as forbs and herbs. Syncrude researchers will also probably plant shrubby willows and birches, as well as black spruce and tamarack trees. “I think we need to start with a few plants to colonize the area, and over time, other plants will come in,” Vitt says. Once the sodium is washed away, those other plants will likely include mosses.

In spring 2012, Syncrude will begin to plant the fen. If Vitt’s plan works, then sometime in the early 2030s a full-fledged fen will become a part of the boreal ecosystem that Syncrude is slowly reconstructing on its oil sands mining lease.

Syncrude is by no means the only oil sands surface mining company reclaiming the environment on its leased land. Every company mining Alberta’s oil sands, even those that perform in situ mining, reclaims the landscape section by section as the bitumen runs out.

With the potential for more than 100 years of oil sands production in Alberta, reclamation is by necessity a broad endeavor. Much of the work is still experimental, which is the reason academics like Vitt, Quideau and Macdonald are involved. Their help is needed to ask the right questions and to find the right answers. Alberta’s government is there to ensure that the mining activities adhere to soil, water and air quality requirements.

Meanwhile, the mining companies say they willingly share reclamation information with each other because they know that the problem of one company can quickly become a problem for the entire industry. Oil sands are a tremendous revenue source for the province and for Canada. If the industry is to continue to thrive, the players must continue to act as good corporate citizens, proving they can return the mines to a natural boreal ecosystem.

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.