by Logan Nagel Monday, November 7, 2016

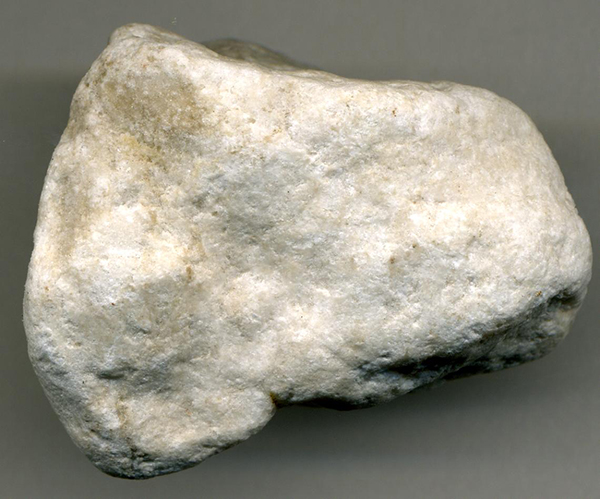

Gypsum forms through a four-stage process, beginning with the formation of bits of nanocrystalline calcium sulfate that gradually assemble into larger aggregates, according to new research. Credit: James St. John, CC BY 2.0

Drywall and plasters made from both natural and manufactured gypsum are commonly used in home and building construction around the world, in part because of gypsum’s widespread availability. Despite its abundance, and its seemingly simple makeup, however, relatively little is known about how the calcium sulfate mineral forms in nature. In a recent study, researchers have shed new light on the multi-stage process by which gypsum grows — and the findings could help develop more efficient ways to manufacture the material.

The new research, published in Nature Communications, builds on a body of earlier work trying to sort out how gypsum forms. Prior to 2012, the generally accepted explanation was that gypsum — or calcium sulfate dihydrate, meaning the mineral carries two water molecules for each calcium sulfate unit — precipitates naturally from aqueous solutions in a straightforward, single-step process. Then, in 2012, a team of researchers, including some of the authors of the new Nature study, challenged that perspective in a study in Science. The group reported that gypsum actually forms in a three-step process: precipitation of nanocrystals of bassanite — or calcium sulfate hemihydrate, with one water molecule for every two calcium sulfate units — followed by the assembly of those crystals into larger aggregates, and finally transformation of the aggregates into gypsum.

The 2012 study was a “big jump forward,” says Alexander van Driessche was complex," he says, adding that the new study puts scientists’ understanding of gypsum formation “much closer” to reality.

In prior research on gypsum, scientists had utilized X-ray diffraction and electron diffraction to investigate dry, powdered samples of the gypsum precursors. For the 2016 study, however, the team, led by Tomasz Stawski of the GFZ German Research Centre for Geosciences, used X-rays generated by a synchrotron particle accelerator to study samples of the gypsum precursors calcium chloride and sodium sulfate mixed in aqueous solution, thus more closely approximating the conditions in which the mineral forms in nature. Although the technique itself isn’t new, it was novel for this application, Stawski says. The new approach allowed the team to observe small crystal clusters form in the solution, he says — the “building blocks which interact and interplay as drivers for gypsum formation.”

Witnessing these building blocks led Stawski, van Driessche and their colleagues to identify a four-stage development of gypsum, updating the earlier three-stage process. In the first stage, noncrystalline bits of calcium sulfate called primary species, which are less than 3 nanometers in length, begin to form. Next, these bits arrange into denser clusters called “domains,” which then self-assemble and begin aligning into larger aggregates in stage three. Finally, in stage four, the aggregates grow and crystallize into gypsum. In the team’s experiments, the entire process took about 25 minutes for gypsum to first appear, with crystallization continuing for more than 80 minutes. This new research also provided an explanation for a previous study, which found that altering the presence and concentration of water and ethanol can determine whether the end result turns out as gypsum, bassanite, a third form of calcium sulfate called anhydrite — which is fully dehydrated — or a combination of the three.

One of the implications of the research is that drywall may be produced more efficiently in the future. Typically, to produce drywall, manufacturers must first dehydrate mined gypsum into bassanite, a time- and energy-intensive process. The study concludes by explaining that learning how gypsum and bassanite form could allow manufacturers to produce bassanite directly, thereby eliminating the need for energy-intense dehydration. While more efficient synthetic routes are now technically possible, van Driessche notes that “this is a fundamental study, and there is sometimes a tendency to be too eager … with what we say about delivering” implementable new processes. “But,” he adds, “we clearly need to make these advances” to improve manufacturing.

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.