by U.S. Geological Survey Sunday, December 27, 2015

Hendrik G. van Oss, a mineral commodity specialist for the U.S. Geological Survey’s National Minerals Information Center, compiled the following information on ferrous slag, which has a number of uses in construction.

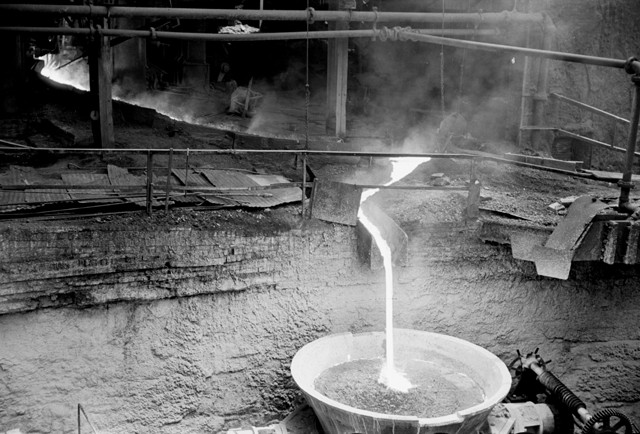

Tapping the slag at a blast furnace in Pittsburgh, Pa., 1938. Credit: Library of Congress.

Iron and steel slag, also known as ferrous slag, is produced by adding limestone (or dolomite), lime and silica sand to blast furnaces and steel furnaces to strip impurities from iron ore, scrap and other ferrous feed materials and to lower the heat requirements of the iron- and steelmaking processes. Ferrous slag forms as a dominantly calcium silicate melt that floats on top of the molten crude iron or steel; the slag is then removed from the liquid metal.

For typical iron ore grades (60 to 66 percent iron), blast furnace slag output will be about 0.25 to 0.30 metric tons of slag per ton of crude iron produced. Steel furnace slag production, after removal of entrained metal, will be about 10 to 15 percent of the crude steel output.

Owing to very low unit values (a few dollars per ton) for most slag compared with the value of crude iron and steel, steel companies generally arrange for outside contractors to remove, cool and process the slag — which involves crushing and screening it and retrieving entrained metal — to prepare it for sale.

The market uses of ferrous slag are determined mainly by the method used to cool the slag. Air-cooled blast furnace slag and steel slag are cooled under ambient conditions, resulting in hard, dense slag that is especially suitable for use as inexpensive aggregates. Granulated blast furnace slag is formed by quenching molten slag in water to form sand-sized glassy particles. Finely ground granulated slag is useful as a partial substitute for Portland cement in concrete and, as such, commands prices in excess of $60 per metric ton. Pelletized or expanded blast furnace slag is cooled using a water jet in order to generate steam and cause air-filled vesicles to form in the slag. The material is used mainly as a lightweight aggregate. Blast furnace slag can be remelted and recooled to form mineral wool, which is suitable for use as thermal insulation.

For more information on iron and steel slag and other mineral resources, visit: minerals.usgs.gov/minerals/.

Based on production levels of crude iron and steel, world output in 2014 of blast furnace slag was estimated to be 300 million to 350 million metric tons. World output of steel slag was estimated to be 160 million to 250 million metric tons.

U.S. sales of processed blast furnace slag totaled about 8 million metric tons in 2014, and steel slag sales totaled about 11 million metric tons. Granulated slag accounted for nearly one-third of the blast furnace slag sales tonnage but contributed nearly 90 percent of the value of the sales (and nearly 80 percent of total ferrous slag sales).

At the end of 2014, only three U.S. blast furnaces could make granulated slag, so the domestic market for this type of slag was heavily import-dependent. At mid-year 2015, only two of these blast furnaces remained operational and future import dependence was expected to increase.

Ferrous slags are co-products of iron- and steelmaking, not waste products. Absent useful applications for slag, most of the historically important steel-producing cities would have been inundated with slag many years ago.

Use of granulated blast furnace slag to replace some of the Portland cement in concrete reduces the carbon footprint of concrete production, and generally improves the quality of the concrete.

Slag can also be used in glass manufacturing and in sewage treatment.

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.