by U.S. Geological Survey Thursday, June 14, 2018

M. Michael Miller, a mineral commodity specialist for the U.S. Geological Survey, compiled the following information on fluorspar, an industrial mineral used in the manufacture of fluorochemicals, aluminum and steel.

Fluorspar is the source of fluorine, an element that is used in a nonstick coating for pans. Credit: ©iStockphoto.com/Witold Ryka

The term “fluorspar” refers to crude or beneficiated material that is mined and/or milled for the mineral fluorite (calcium fluoride). Fluorite is a nonmetallic mineral, containing 51.1 percent calcium and 48.9 percent fluorine. Industry practice has established three grades of fluorspar: acid grade (containing more than 97 percent calcium fluoride), ceramic grade (85 to 95 percent calcium fluoride) and metallurgical grade (normally 60 to 85 percent calcium fluoride). Fluorspar’s uses have grown and changed in the last 100 years; today, the most important markets are fluorochemical production, aluminum refining and steelmaking.

In the U.S., most acid-grade fluorspar is used in the production of hydrofluoric acid, which is primarily used in manufacturing various fluorocarbon chemicals that are used as refrigerants, foam-blowing agents and solvents, and in the production of high-performance plastics. Hydrofluoric acid also is used in manufacturing computer chips and high-octane gasoline, stainless steel pickling and uranium fuel processing. Acid- or ceramic-grade fluorspar also may be used to manufacture enamels, glass and fiberglass, and welding rod coatings. Metallurgical-grade fluorspar is consumed mainly in steelmaking, but is also used in making portland cement and casting iron and steel.

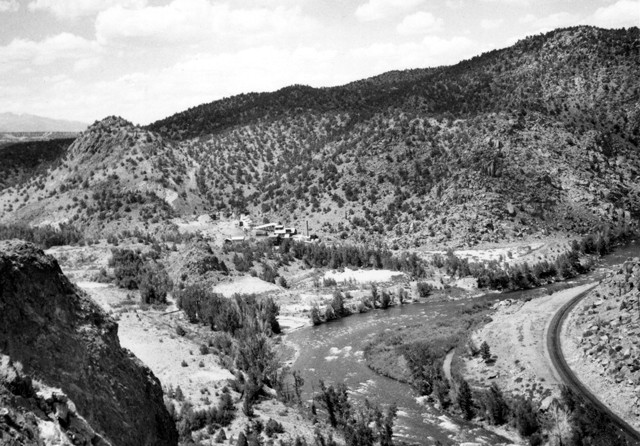

Colorado-American fluorspar mine in Chaffee County, Colo., circa 1945. The United States was a major producer of fluorspar from World War II until the late 1960s. Credit: U.S. Geological Survey Photographic Library

The leading use of hydrofluoric acid is in the production of fluorocarbon chemicals, so the phaseout of the first generation of fluorocarbons (chlorofluorocarbons or CFCs) in the 1990s — as called for by the Montreal Protocol — caused world demand for fluorspar to decrease from its peak in 1989. In the 1990s, however, more ozone-friendly fluorocarbon compounds — primarily hydrofluorocarbons or HFCs, which do not deplete the ozone layer — were developed to replace CFCs; many of these replacement compounds actually contain more fluorine than the CFCs they replaced, so fluorspar demand slowly rebounded.

However, HFCs are now being targeted for elimination as part of an international response to climate change because they have a strong potential to increase global warming. For example, HFC-134a (widely used as a refrigerant) has a global warming potential (GWP) of 1,300 compared with that of carbon dioxide, which has a GWP of 1. A new set of fluorine-based compounds may arise to replace HFCs just as HFCs were developed to replace CFCs, but they face stiff competition from other chemical compounds such as ammonia, carbon dioxide and hydrocarbons.

For more information on fluorspar and other mineral resources, visit http://minerals.usgs.gov/minerals.

The United States produces only small amounts of fluorspar as a byproduct of limestone mining, but a new mine is set to go into production in Kentucky later this year or early next year.

Reported U.S. fluorspar consumption in 2009 was 400,000 metric tons, of which 380,000 tons was acid grade and 20,000 tons was metallurgical grade.

World production in 2009 was about 5.1 million metric tons, a decrease of about 16 percent compared to 2008, reflecting world economic conditions.

China is the world’s leading producer and consumer of fluorspar.

The name fluorite is derived from the Latin word “fluere” meaning to flow, and was first used by mineralogist J.D. Dana in 1868.

Although fluorite has been used for ornamental purposes since ancient times, Basilius Valentinus at the end of the 15th century and Georgius Agricola in 1529 recorded its earliest uses as a flux. Fluorspar has been widely used in steelmaking as a flux since the introduction of basic open-hearth furnace technology in the late 19th century, and in basic oxygen and electric arc furnaces today.

Fluorspar is the source of fluorine in the compound polytetrafluoroethylene (PTFE), which is used as a nonstick coating for pans and other cookware.

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.