by Yael R. Glazer, F. Todd Davidson and Michael E. Webber Thursday, October 22, 2015

Natural gas is flared as oil is produced in North Dakota. Credit: Tim Evanson, CC BY-SA 2.0.

In the process of providing the energy we consume, oil and gas producers around the world use large quantities of clean water, generate massive amounts of wastewater, and purposefully set ablaze a portion of their natural gas production. The volume of water is tremendous, and enough energy is “flared” to power more than 50 million U.S. homes every year. In many places in the world, the freshwater needed for such operations is scarce; and natural gas flaring releases greenhouse gases and produces light pollution. Given the recent boom in oil and gas production in the U.S., it seems that these issues may not be going away anytime soon. However, with some clever engineering, we could pit these environmental liabilities — wastewater production, overuse of freshwater and gas flaring — against one another to solve all three at once.

A wastewater impoundment in western Texas that is associated with hydraulic fracturing. Credit: Jared Garrison.

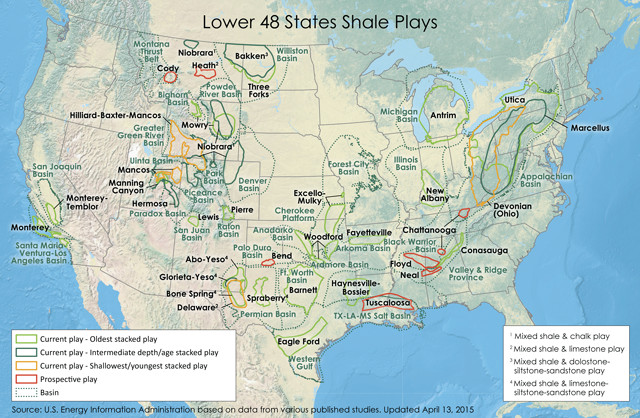

Over the last decade, America has seen its oil and natural gas industry reborn. After several decades of stagnation and decline, oil and gas production has increased substantially thanks in large part to technological advancements in hydraulic fracturing (“fracking”) and horizontal drilling, which have made it economical to recover resources from shale formations. The U.S. Energy Information Administration estimates we now have access to 665 trillion cubic feet of natural gas and 58 billion barrels of oil from the numerous shale formations across the country. Net imports of oil and gas have fallen steadily since the shale boom took off in 2005; we now import less than half of the oil we consume and we are building gas export facilities. This production has had significant economic benefits for the United States. But the economic activity has also created growing pains by significantly increasing natural gas flaring and exacerbating demand for local water resources.

Fracking is water intensive: 2 million to 9 million gallons of water are required to complete and ready a single well for production. The tens of thousands of wells drilled every year require hundreds of billions of gallons of water. And although water use by the oil and gas industry is typically less than 1 percent of the country’s total water use, its impact can be substantial at the local level. This is especially true in areas that are already water-stressed or prone to droughts and where the majority of the water resources are already allocated for other purposes such as agriculture or municipalities.

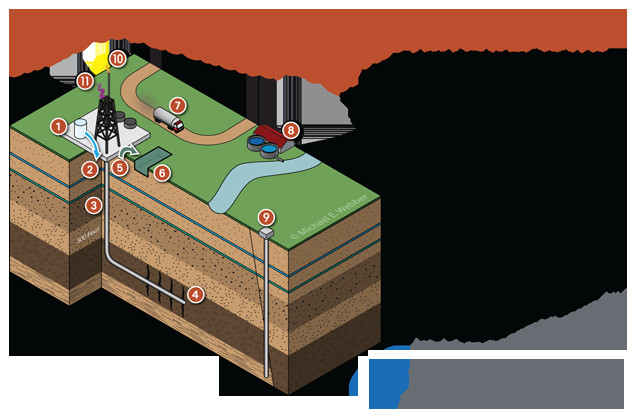

Fracking also generates large volumes of wastewater that must be disposed of and/or treated. Wastewater is composed of three parts: drilling muds, flowback and produced water. During well drilling, drilling muds are used to keep the drill bit cool and to clear the cuttings out of the well, among other purposes. Flowback includes a portion of the water used during the fracking process that returns to the surface within a few weeks of the fracking operation. Produced water is water that occurs naturally in the formation that, during well operation, comes to the surface along with the oil and gas. All of this wastewater needs to be managed.

The quality and quantity of wastewater varies from one region to the next and depends on the geology of the shale formation from which the oil and gas is produced. This wastewater contains a multitude of components, including hydrocarbons, salts, minerals, naturally occurring radioactive material, and many other constituents. Concentrations vary significantly based on the shale. One of the primary measures for determining the quality of the water is the Total Dissolved Solids concentration, or TDS. The dissolved solids can be composed of a variety of minerals, but often consist primarily of salts. For reference, high-quality drinking water has a TDS level of less than 500 milligrams of solids per liter of water (mg/L); the World Health Organization considers anything above 1,200 mg/L unacceptable to drink. Seawater has a TDS level of about 20,000 mg/L. The wastewater produced at some oil and gas wells has TDS levels approaching 350,000 mg/L, although the range tends to be from 40,000 mg/L to 250,000 mg/L. Not only is this wastewater far from suitable for drinking, but it is a hazard to surface waters, plants and animals if not managed properly.

Management practices for handling wastewater can include injecting it deep underground, presumably never to be seen again (known as deep-well injection); evaporating it in pits; and treating it for potential beneficial reuse (for purposes such as fracturing new wells, irrigating croplands, spreading on roads for de-icing, or discharging to surface water). While deep-well injection neatly disposes of the problem, injection of wastewater has also been correlated with the rise in earthquakes in states like Oklahoma and Ohio that aren’t traditionally considered seismically active. Also, deep-well injection is not an option everywhere. Some oil-producing states like Texas and Oklahoma have many thousands of disposal wells, but others, like Pennsylvania (home to parts of the Marcellus and Utica formations), have only a handful of deep-well injection sites. That leaves operators in Pennsylvania with few and very costly options to dispose of their wastewater, such as trucking it to neighboring states.

The calls to minimize demand for freshwater by oil and gas production, and to better manage wastewater generated in the process, have grown louder in recent years. And given that U.S. oil and gas production is still at record levels despite low prices, it seems all the more important for oil and gas developers to address these concerns.

Known environmental risks of producing oil and natural gas from shale using hydraulic fracturing. Credit: Jeffrey M. Phillips.

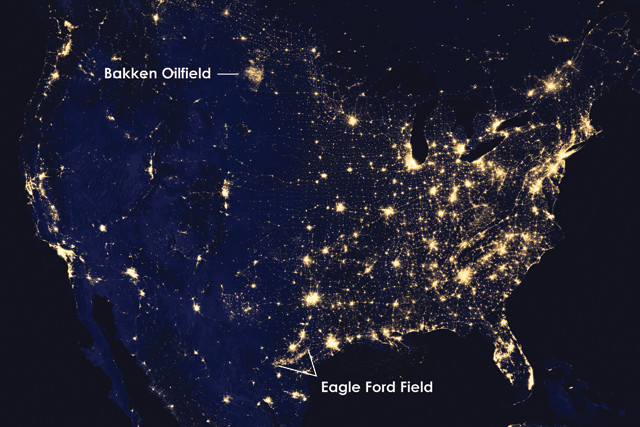

Natural gas flaring has historically been associated with autocratic countries where natural resources far exceed demand and environmental regulations are less stringent, but it is also a growing problem in the United States because of the growth in shale oil and gas operations. In Texas alone, the percentage of total natural gas production that is flared has seen a tenfold increase over the last several years. In the Bakken Field of North Dakota, 30 percent of natural gas production has been flared in recent years.

Natural gas flaring, especially in the Bakken Field in North Dakota and the Eagle Ford Field in Texas, reveals significant industrial activity. Credit: NASA Earth Observatory/NOAA NGDC.

Natural gas is flared in western Texas. Enough energy is flared worldwide each year to power more than 50 million modern homes. Credit: Jared Garrison.

It is logical to wonder why operators would choose to burn a potential revenue stream. Part of the answer is that in regions where natural gas is produced alongside oil, there is often insufficient infrastructure to bring the gas to market. Once rock is fractured to produce the oil, the gas cannot be contained; as a result, many operators choose to flare the natural gas in a controlled flame. Alternatively, they could simply vent it into the air. If left unburned, however, an open flame or spark could cause vented gas to explode uncontrollably, posing a serious safety risk. In addition, the dominant constituent of natural gas is methane, which is 20 times as potent a greenhouse gas as carbon dioxide. By burning the gas in a flare, the methane is converted primarily to carbon dioxide and water vapor, so flaring is actually better for the environment than venting.

Logistical and additional safety challenges offer more reasons why natural gas is flared. The flow rate and pressure of gas flowing out of a well inevitably fluctuate. Even when proper infrastructure is in place, there are times — such as a sudden surge in the flow of gas — when it is safer to flare the gas than to try to move all of it to pipeline. Maintaining an active flare allows excess gas to be purged from the system if it cannot be directed to a pipeline or utilized for other beneficial uses, such as powering a generator.

Locations of oil- and natural gas-rich shale deposits in the U.S. Credit: K. Cantner, AGI.

Aerial view of oil and gas well pads in Midland, Texas. Credit: Margaret Cook.

A novel solution for all three environmental issues is to repurpose the flared natural gas as an energy source that can be used to treat and clean wastewater generated during the drilling and completion of wells. This approach addresses the three concerns simultaneously by beneficially using the gas that would otherwise be flared, reducing the volume of wastewater that requires disposal, and generating a considerable volume of treated water that could be recycled and used to frack subsequent wells, rather than continuing to draw on existing freshwater supplies.

Along with other colleagues, two of us (Glazer and Webber) published an initial study in Environmental Science & Technology Letters in 2014 analyzing the technical feasibility of treating wastewater with flared gas. The study revealed that, in 2012, Texas flared enough gas to generate 180 million to 540 million cubic meters of treated water — depending on which water treatment technology is considered — representing 1 to 2.4 percent of total statewide water demand for all purposes. In fact, this is enough water to meet the annual needs of the entire oil and gas sector in Texas.

The Texas study helped to highlight the possibility for this novel approach. Now the remaining task for those interested in using flared gas for water treatment to help manage their wastewater is to work out the logistics, including determining the optimal treatment technology based on a variety of factors. Such factors include the salinity and quality of the wastewater (what constituents are in it and in what amounts); the use for the treated water (which will dictate how clean it needs to be); the portability of the technology (how quickly and easily the treatment technology can be taken from one location to another); availability of local surface and groundwater; distance and availability of disposal wells; local, state and federal regulations; and, likely above all else, cost. Some operators are already treating their wastewater, mainly for the purpose of reusing the water to fracture and complete a subsequent well. In an effort to reduce costs, the industry has worked diligently to minimize the amount of treatment — and thus amount of energy required to treat it — required for this purpose. In fact, many companies tout their ability to frack using water with TDS levels several times higher than that of seawater.

Although many operators reusing their wastewater are implementing minimal treatment solutions, some explore more energy-intensive options to remove the total dissolved solids, either because their specific well operations require freshwater or because they are interested in other options for beneficial reuse of the water. Removing the total dissolved solids in the wastewater requires additional treatment steps such as thermal distillation or reverse osmosis, which significantly increase the energy required for the treatment process. Higher energy requirements would normally translate into higher costs (to purchase the necessary fuel to power treatment). However, in the case where natural gas is already onsite and being flared, the energy for the treatment is essentially free and readily available.

By using a thermal treatment option — one that uses heat instead of electricity — the flared gas can provide the necessary fuel to operate the water treatment process. Numerous heat-based water treatment options exist, including multistage flash distillation, multi-effect distillation and membrane distillation. Distillation methods create steam by boiling the water, a technique that has been around since Roman times. With proper pretreatment, the steam will be nearly pure water that rises through a column before eventually being captured as condensate. This process is very robust, but also very energy-intensive. These treatment technologies can readily use natural gas as their energy source and can bring the wastewater to freshwater standards, giving the operators more options for beneficial reuse than lower-quality water.

Operators have many water treatment options they can choose from in addition to thermal distillation techniques. The quality of the wastewater along with the desired use for the treated water help dictate which treatment technologies are most appropriate. For example, should they choose to reuse the treated water to frack a subsequent well, it might be sufficient to remove only the solid constituents, grease and oils. This is often achieved through a water treatment technique known as “floc and drop” in which chemicals are added to the wastewater to help the solid particles clump together and make it easier for them to settle to the bottom. This process is often followed by a basic filtration step. At this point, the water is often considered clean brine and can be mixed with freshwater as needed to lower (dilute) the TDS concentration. If the operator needs to treat the water to meet freshwater standards, they will follow the pretreatment steps with a technology like thermal distillation to remove the TDS.

Natural gas can also be used as a fuel source to power an engine or generator. In this case, the operator could choose technologies that require either mechanical power or electricity to clean the wastewater. Examples of these technologies are mechanical vapor recompression and reverse osmosis.

Aerial view of well pads in North Dakota. Credit: ©Chris Boyer, Kestrel Aerial Services, Inc.

Credit: Glazer, Davidson and Webber.

The results of our Texas pilot study were revealing. Even using the most energy-intensive treatment options, like thermal distillation, Texas flares enough gas to treat hundreds of millions of cubic meters of wastewater. The volume of treated water would be enough for drilling and completion of 10,000 to 30,000 new wells, between 35 and 100 percent of the wells that were drilled and completed in the state in 2014. In fact, the pilot study showed it is technically feasible to treat all of the wastewater with the amount of flared gas that is available. The positive results from the Texas study, and the fact that the issues of water management and flaring associated with oil and gas production are occurring across the country (and around the world) suggest that similar successes can be achieved elsewhere.

The study did not address the economic feasibility of such treatment options, which may be affected by the recent decline in oil prices. On one hand, the fall in prices might put oil and gas operators in a position where they think they cannot afford to implement novel solutions to manage flared gas and water resources at production sites. On the other hand, operators are currently looking for every way possible to cut costs, and putting the flared gas to use and avoiding costs associated with water procurement and wastewater disposal might be a great way to do just that.

The environmental challenges of shale production are real, but they are manageable. Creative design that integrates two waste streams (wastewater and flared gas) to avoid using a precious resource (freshwater) can make these environmental problems much easier to handle. It’s worth asking ourselves: In the future, will oil and gas companies become oil, gas and water companies?

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.