by Timothy Oleson Friday, April 11, 2014

The largest shake table experiment ever conducted shook this full-size seven-story condominium built at the Japanese National Research Institute for Earth Science and Disaster Prevention's Earth-Defense facility ("E-Defense") in 2009. Credit: John van de Lindt

On a muggy day in mid-July 2009, a lone seven-story condominium complex northwest of Kobe, Japan, was violently shaken by seismic forces similar to those that struck Northridge, Calif., in 1994 — only stronger. Onlookers watched the 23-unit, wood-frame tower sway and bounce while, inside the building, furniture toppled and plates clattered to the floor.

No one was hurt during the highly localized event and there was only minimal damage, in part because the building’s wooden skeleton had been augmented to better resist earthquake shaking, but also because the whole event — from the seismicity to the partially furnished building — was just a test.

It was the largest seismic experiment ever conducted on a full-size building, and it was carried out on the world’s biggest earthquake-simulating shake table inside a cavernous hangar at the Japanese National Research Institute for Earth Science and Disaster Prevention’s Earth-Defense facility (“E-Defense” for short) in the city of Miki, Japan. In a series of tests, engineers programmed the massive 20-meter-by-15-meter table to mimic the 3-D ground motions experienced near the epicenter of California’s magnitude-6.7 Northridge earthquake, amplifying the intensity of the synthetic seismicity to as much as 1.8 times that of the actual quake.

In 1994, real seismic waves wreaked havoc on the Los Angeles area. Sixty people were killed and billions of dollars in damages resulted as numerous human-made structures failed, including many older wood-framed apartment complexes and houses that couldn’t stand up to the shaking.

Aside from a coat of paint and some key structural modifications built into it from the outset — including a steel support frame on the ground floor, “tie-down” rods to anchor the upper floors to the base and sturdier-than-usual wood walls — the seven-story guinea pig constructed at E-Defense in 2009 superficially resembled wood-frame complexes common in quake-prone areas like Southern California, the San Francisco Bay Area and elsewhere.

Such experiments — intended to gauge how the building as a whole fared when those modifications were integrated — have not always been possible. Although shake tables have been around for more than a century, only within the last few decades have tables capable of supporting and shaking full-size buildings with realistic seismic vibrations come online. These big tables have offered an array of new options for data collection and assessment to supplement computer-based modeling and physical testing of individual components or scaled mock-ups of whole structures. And they have given engineers and builders vital new tools in their efforts to help buttress not only buildings, but also bridges, pipelines, wind turbines and other structures against the forces of nature.

The seven-story tower in the early stages of construction at E-Defense in Japan. Credit: John van de Lindt

Shake tables are, at their most basic, essentially just platforms that can be vibrated in a controlled and regular manner. The first known shake table was developed in Japan in the late 19th century and was driven by hand. Subsequent innovations included mechanical devices like springs, swinging pendulums and eccentric-mass-weighted wheels along with electric motors to drive tables back and forth in a single dimension. Early oil-filled pistons came into use with shake tables in the mid-20th century and were the precursor to modern tables.

Driven by large hydraulic actuators — cylindrical chambers inside which the movement of a piston is powered by pressurized hydraulic fluid — the precise motions of today’s tables are electronically controlled by way of software. Some tables are equipped to recreate full six-degrees-of-freedom 3-D motion — that is, linear movement along and rotations about three axes — and typically move no more than a meter from center in any direction. Others operate with more limited ranges of motion. Operators can preprogram desired shaking patterns, which, in the case of simulated seismicity, are often taken from records of actual ground accelerations in past earthquakes.

Numerous shake table facilities exist worldwide today, although most are relatively small, measuring only a few meters or less on a side. Only a few are big enough and have the payload capacity to vibrate entire buildings.

The 2009 tower tests in Miki were the capstone experiments of a four-year $1.4-million project funded through the National Science Foundation’s (NSF) Network for Earthquake Engineering Simulation (NEES), called “NEESWood.” The entire structure was erected at E-Defense and placed atop the 300-square-meter shake table, which is capable of supporting up to about 1,200 metric tons. The building was instrumented with cameras, potentiometers, accelerometers and LED light sensors — more than 300 sensors in all — to record in minute detail the building’s reactions to the seismic shaking as well as any damage sustained.

Over two weeks, an international team of academic researchers and their partners in government and industry put the structure through five tremors. The first two tested the stabilizing effect of the steel-framed bottom story in simulated earthquakes that were 0.6 and 1.4 times as intense as the Northridge quake. For the third and fourth tests — at 0.6 and 1.2 times the Northridge intensity — the bottom story was braced to the shake table (effectively making it part of the table) to remove its influence and test the durability of the top six floors on their own. Likewise, for the culminating and largest test, held in front of a crowd of about 600 observers, the wooden portion of the building was intentionally left to bear the brunt of a magnitude-7.5 quake — bigger than anything California has seen since 1906 — on its own.

“I don’t know if anyone was as nervous as I was” going into that last test, says John van de Lindt, a structural engineer at Colorado State University and the project’s principal investigator. “When you see the shake table move, it’s really moving exactly how the ground moved at some location, except we can scale it up and down depending on what type of intensity we want,” van de Lindt says. “If you were standing there, it would feel almost identical” to a real earthquake.

When the final bout of shaking was over, after less than a minute, the building was not only still standing, but as in the earlier tests, it had suffered even less damage than anticipated — mostly cracked drywall, with no significant structural damage.

“It wound up being a very successful test” that validated the team’s design approach and “definitely changed the landscape” for designing new earthquake-resistant wood buildings, van de Lindt says. “We certainly know that we can build those buildings to perform” the way the test building did, he says. “It’s a matter of taking a lot of what we learned and applying it.”

Credit: Kathleen Cantner, AGI

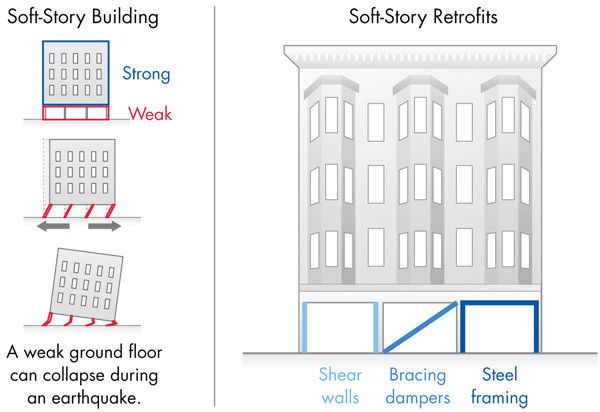

In the last few years, van de Lindt and his colleagues have been doing just that, applying lessons from the NEESWood project to a follow-up effort. In addition to focusing on new construction, they’re also “looking at reducing the seismic risk of existing buildings,” he says, particularly of so-called soft-story buildings. Soft-story buildings have one or more floors of residential space resting above a more open floor, often used for parking or retail space, at street level. These open floors are known to be structurally weak, leaving the buildings vulnerable to heavy shaking.

Damage on the garage level of a soft-story building at the corner of Beach and Divisadero Streets in San Francisco's Marina District after the Oct. 17, 1989, Loma Prieta earthquake. Credit: U.S. Geological Survey/J.K. Nakata

In San Francisco alone, there are about 2,800 such buildings — including many in historic neighborhoods such as the Mission, Pacific Heights and the Marina District, among others. These house roughly 58,000 people along with 2,000 businesses, according to a 2009 report for the city by the Applied Technology Council (ATC). The report concluded that 1,200 to 2,400 of these structures would likely suffer severe damage or outright collapse if a magnitude-7.2 earthquake were to strike on the nearby portion of the San Andreas Fault. The finding prompted the city to pass a mandatory ordinance in 2013 requiring soft-story buildings with three or more stories and five or more residential units to be evaluated and, if deemed necessary, retrofitted to meet building strength standards issued by the Federal Emergency Management Agency, the American Society of Civil Engineers or others. (Specific retrofits required vary on a case-by-case basis, but could include, for example, steel framing or additional “shear walls” to better absorb lateral shaking.)

“We have at-risk buildings out there — these are dangerous buildings,” van de Lindt says. Such buildings collapsed in the Northridge quake, and in the Bay Area, they collapsed in the 1989 Loma Prieta quake, he notes. “But these soft-story buildings can be retrofitted.”

Last summer, he again headed a team through a series of shake tests on a wood-frame complex. This time, the test subject was a functioning four-story replica of the sort of soft-story residential building that the ATC report had highlighted. The goal was to see how well it fared with several different quake-resistant retrofits, as opposed to testing construction with such features built in from the outset.

The first retrofit replaced the standard plywood walls on the first floor that would be subjected to the lateral and vertical forces in an earthquake with cross-laminated timber (CLT). Pieced together from slats of dimensional lumber — two-by-fours, for example — CLT, which was developed in Europe in the 1990s, is like “plywood on steroids,” van de Lindt says. It’s better able to withstand ground motion on the ground floor and reduce the shaking that travels up to the higher floors where people live. The team then tested a steel “special moment” frame and an anchor tie-down system similar to those used in the NEESWood project, as well as fluid-filled shock absorbers known as seismic dampers.

As in the tests four years earlier, the upgrades to the soft-story building proved their value. “In a maximum credible earthquake … which is 1.5 times what we design for by code, [the building was] virtually undamaged,” van de Lindt says, again aside from some drywall cracking. Overall, the retrofits allow engineers to “dictate exactly how the building deforms in an earthquake, and that gives it much better performance,” he says.

Like the NEESWood project, the soft-story tests were only possible because of the availability of a shake table capable of bearing a large load. The 2013 tests, however, were not carried out in Japan, but on a table at the University of California at San Diego (UCSD).

Measuring 12.2-meters-by-7.6-meters and able to hold a payload of about 2,000 metric tons, UCSD’s table is the second largest in the world after E-Defense. Now in its 10th year of operation, the UCSD table has made many different structures tremble.

Jose Restrepo, a structural engineer at UCSD and one of the principal investigators at the facility since it opened in fall 2004, has had a hand in many of the tests. He has used the table to look at structural walls in a slice of a seven-story reinforced concrete building; the seismic response of wind turbines and precast concrete parking garages; the behavior of novel flexible bridge foundations; and damage to nonstructural elements — including equipment in an intensive care unit and an operating room, computer servers, a working elevator and other systems — in a five-story, full-scale (though not full-size) mock hospital made from reinforced concrete.

In general, Restrepo says, several years of preliminary work go into complex projects before full-scale shake table tests are performed on a structure. Such long timetables are necessary given the amount of work, risk and money involved: Project budgets tend to range from about $500,000 to $5 million, he says, even when construction labor and materials are provided at cost. Planning starts well before a grant proposal is even submitted, he says, during which time research consortiums are assembled, projects are outlined and goals are established. If a proposal is funded, teams usually spend the first few years of a grant doing computer modeling and smaller-scale testing of individual building components before construction, which itself can take months, begins on a full-scale structure on the shake table.

With all the forethought, researchers typically go into full-scale tests with a good idea of how their structures will behave. So the atmosphere for a big test is usually relaxed, Restrepo says. “But as we get to the very largest motions near the end of the test, it is tense,” he says, “because you need to be aware of the potential for collapse.” Although outright collapse is not often a primary goal of shake table testing, by pushing structures to their limits, “you can gain more information that in the end is going to serve your purpose and is going to percolate to society,” Restrepo says.

Aside from costs associated with specific projects, large-scale shake tables are, not surprisingly, expensive to construct, operate and maintain. The original price tag for the UCSD facility, which was built and has operated since opening predominantly with NEES funding from NSF, was $10 million. And this pales in comparison, Restrepo notes, to the roughly $500 million spent to build the E-Defense facility in Japan, which was completed in 2005. Despite the high cost, the value of such facilities is clear, according to the researchers who use them. Reports on the state of earthquake engineering research in recent years, including, for example, National Research Council reports prepared for the National Academies, have also stressed their importance in addressing challenges in the field going forward.

Simply put, “before NEES and E-Defense and these types of sites, you could test a small building, but now we can actually test full-size buildings,” van de Lindt says. Having this capacity is important, he says, because the effects of earthquake shaking on buildings and structures don’t always scale with size in a known way. Although seismically induced displacements of wooden components from their original positions can be translated from mock-ups to real structures using laws of similitude, van de Lindt notes, “what doesn’t scale in wood is the damage.” And assessing damage is, after all, one of the main goals of shake table tests.

Similarly, the behavior of welds between pieces of steel doesn’t scale well, and with concrete, “you cannot really scale by more than three” before size-dependent effects emerge, Restrepo says. “So we can scale to 1-to-2, perhaps to 1-to-3,” he says, but beyond that “you need to be aware that there will be a lot of differences” between models and real structures.

Restrepo also notes that “sometimes it’s cheaper to build at full scale because you use off-the-shelf supplies and [established construction] methods.” It can cost more to build and test structures using scaled-down parts — doorframes or partition walls or brackets, for example — if parts have to be custom-made and construction protocols have to be adapted. In general, he says, “the best thing to do is test at full scale.”

The ability to gauge how all the parts of a building perform together, as an integrated whole rather than as individual components, is another major advantage offered by large shake tables.

Based on shaking tests of individual walls and other parts “against the kind of lateral loads that might develop in an earthquake,” the cold-formed steel (CFS) industry has “developed design guidelines for engineers [suggesting] how they could build whole buildings” made from CFS, says Benjamin Schafer, a structural engineer at Johns Hopkins University. Several years ago, Schafer and his colleagues became interested in how a building made almost entirely from CFS — thin sheets of steel bent into desired shapes — would behave in an earthquake. “Essentially, there were no data on the detailed performance of a real building,” he says.

So his team pitched an idea to test a two-story CFS building, received funding from NSF, and in 2011, began preliminary testing. Then, last summer, they constructed the full-scale building at the University at Buffalo’s shake table facility — also funded through the NEES collaboration — which houses two movable 7-meter-by-7-meter shake tables that can be slid apart or operated side-by-side as a single table depending on the application. (Like the table at E-Defense, the Buffalo tables can recreate full 3-D motion; UCSD’s table, although originally designed to do the same, currently only recreates lateral motion in one dimension.)

Schafer and his team subjected their CFS building — first just the bare steel skeleton, and then finished with walls sheathed in gypsum board, exterior insulation, stairways and other standard features — to synthetic earthquakes that were again similar to the 1994 Northridge event. In both cases, the building’s response was “much better than we had anticipated,” he says, with damage limited to cracking of gypsum drywall and around windows and doors, but without significant structural damage.

Based on these tests, it became clear that were such a building to endure a real earthquake of that magnitude, “absolutely that building would be green-tagged [as safe to re-enter and occupy afterward],” Schafer says. But existing engineering models suggested that it should have suffered serious damage in such a quake, to the point of requiring substantial repairs or possibly demolition, he says. “So, the gap between our ability to predict the real behavior and what we observed was huge.”

There is still a wealth of data to analyze that ought to help improve engineering models, but the value of the experiments, which would not have been possible “if it weren’t for having the kind of facility where we could push a real building at those demands,” Schafer says, is already evident.

As recent images from Wenchuan, China, in 2008; Port-au-Prince, Haiti, in 2010; Christchurch, New Zealand, in 2011; and countless other past earthquakes remind us, it isn’t ground motions themselves that take lives but, far more often, failure of human-made structures caused by the shaking that does. Ultimately, the goal of earthquake engineers is to help minimize harm to humans and the built environment by influencing and improving building codes and practices.

Historically, such improvements have mostly been reactionary and based on observations of damage from major earthquakes. The first Uniform Building Code, published in 1927 by what was then the Pacific Coast Building Officials (later the International Conference of Building Officials), followed severe early-20th century earthquakes in California. The 1933 Long Beach earthquake, which toppled numerous brick and unreinforced masonry buildings, including many schools, led in large part to passage of California’s Field Act, which mandated improved standards for those buildings. And the 1971 Sylmar earthquake again led to updated codes in California after hospitals and schools were severely damaged.

“Every earthquake was killing people left and right,” Restrepo says, so “the main engineering [goal] was to come up with a way to prevent these endemic collapses of buildings.” And along with improved understanding of earthquake forces and mechanisms, engineering advancements have indeed contributed to prescriptive codes, resulting in fewer collapses. Since about the 1990s, Restrepo says, the trend in earthquake engineering research has been to study designs and construction methods that surpass mandatory standards using an approach called performance-based seismic design (PBSD).

“What a lot of people don’t understand is that current design code for floor space design, which is what we use for 99.9 percent of buildings, is actually a minimum requirement,” van de Lindt says, intended to keep people safe from collapse but not necessarily to prevent serious damage to structures. The idea behind PBSD, he says, “is that the stakeholders and building owners — the people who have a vested interest in a particular building surviving and performing well in an earthquake — can make a decision to build beyond, or better, than current code.” Central to the emergence and growth of PBSD, which requires testing of whole structures at full scale, has been the capabilities afforded by large-scale shake tables.

“The process to begin to transfer the knowledge into the building codes is immediate,” Schafer says, but it still takes time for research results to filter through academia and industry and be integrated into building standards, whether minimum or performance-based. That time frame can vary from a couple of years or less to up to a decade depending on the nature of the change and who is considering it. But with shake tables and other modern tools at their disposal, engineers have been able to begin moving beyond reactionary prescriptions based on past earthquakes, and help prepare our buildings for the future shaking that will inevitably come.

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.