by Julia Rosen Thursday, August 7, 2014

Credit: Kathleen Cantner, AGI.

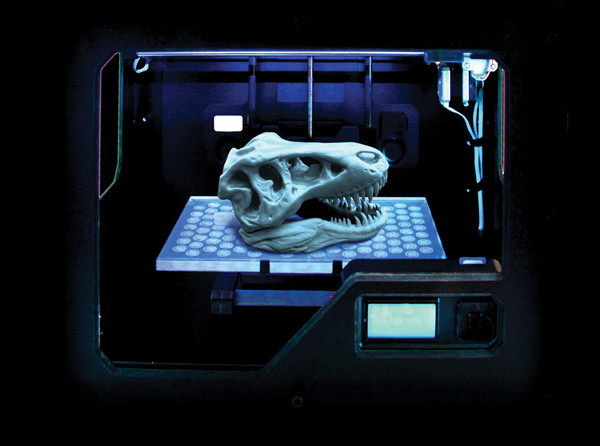

Franciszek Hasiuk prints T. rex skulls in Iowa State University's school colors using a 3-D printer. He uses these and other printed "fossils" for teaching and outreach. Credit: Franciszek Hasiuk.

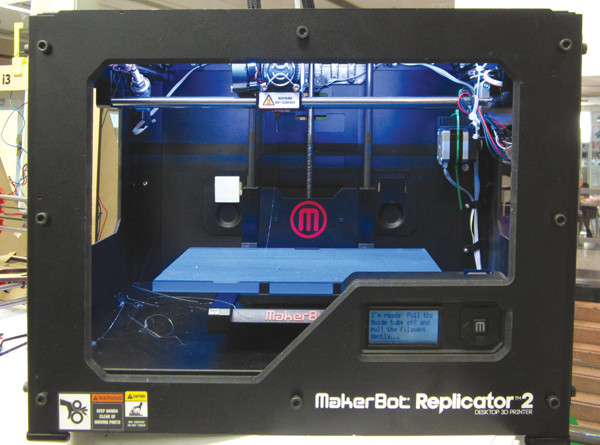

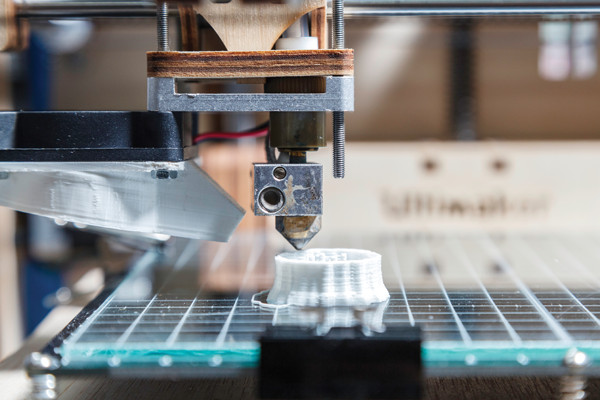

In a modest, low-slung room tucked in the back of Oregon State University’s Pacific Slope Archaeological Laboratory, a small box sits quietly buzzing on a countertop and hiccuping each time the mechanical arm inside abruptly changes direction. Behind the box’s clear walls, an object has started to take shape. It looks something like a lumpy plastic pancake, but closer inspection reveals sharp edges and a scalloped surface. It is actually a half-finished replica of an arrowhead excavated from Cooper’s Ferry, Idaho, an idyllic spot along the Salmon River inhabited by early North Americans 13,000 years ago. The box producing it — a 3-D printer called a Replicator 2, designed by the Brooklyn-based company, MakerBot — is much newer.

Loren Davis, a professor of archaeology at Oregon State University (OSU), scanned the artifact using a rotating 3-D scanner, translated the results into printable code, and uploaded the model to Thingiverse.com — MakerBot’s digital warehouse of free, publicly available 3-D patterns. Davis hopes that, one day, all fossils and artifacts will receive the same treatment.

The rapid proliferation of 3-D printing technology that began in the early 2000s sent ripples of excitement through the tech world and beyond; some pundits predicted 3-D printing would transform everything about modern life. Until a few years ago, however, the high price of printers put them out of reach for most academic researchers and hobbyists. Now, more affordable printers like the MakerBot — which costs about $2,000 — have broken this barrier, and geoscientists have started testing the waters.

After all, from the delicate geometry of a crystal lattice to the sweeping strata of an anticline, geology is an inherently 3-D discipline. Three-dimensional printing offers the chance to make those structures replicable, communicable and malleable. And it can make objects themselves “open source,” enabling wider access to specimens for students and giving researchers the power to handle and manipulate the natural features they study. The question is not whether 3-D printing has a place in earth science, but rather, if it will prove transformative.

The MakerBot Replicator 2 is a relatively inexpensive 3-D printer used by many geoscientists. Credit: ©Peabodybore, CC0 1.0 Universal.

The term “3-D printing” only describes half of the story; the printers must first be told what to produce. When replicating existing objects, scientists must capture their geometries using 3-D scanners and then convert the output into printable patterns. For theoretical objects, they can generate models using software.

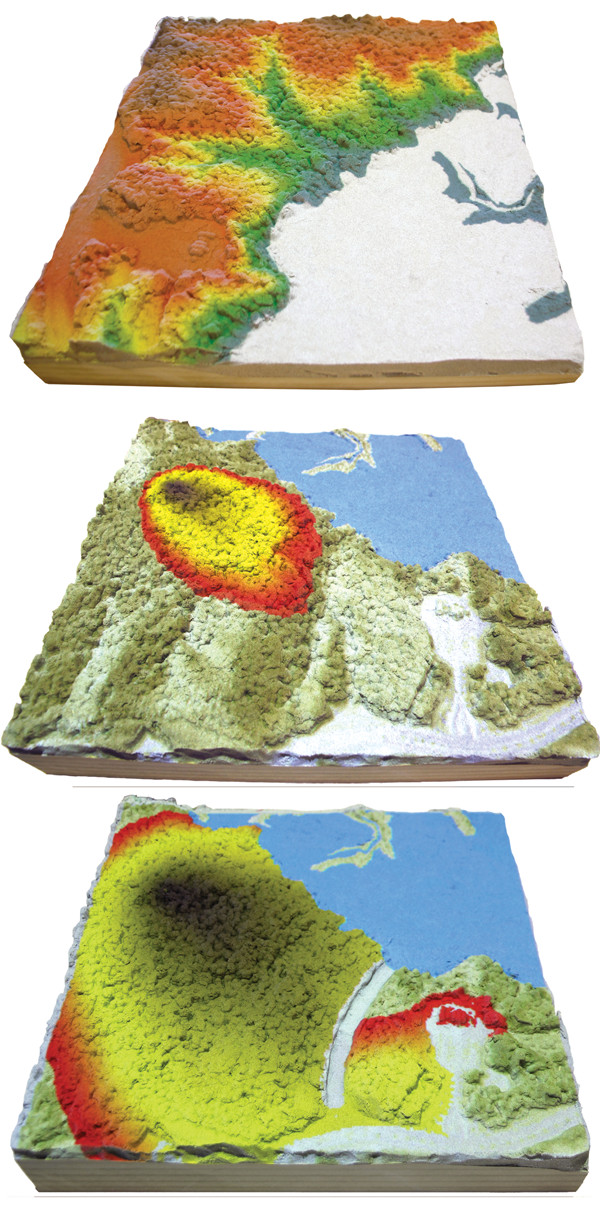

Different printers work in slightly different ways, but the basic process — more formally known as additive manufacturing — remains the same. Printers deposit successive layers of material while gradually moving the printed object up or down with respect to the print head. A dedicated human could mimic the process and “print” a coarse model of a mountain range by cutting out pieces of foam board representing every contour line on a topographic map and stacking them on top of each other.

Basic 3-D printers like the MakerBot use spools of plastic filament, which come in a kaleidoscope of colors and types, including flexible plastics that can be reshaped in hot water and even a bioplastic made from corn. The printer melts and extrudes these plastics at temperatures topping 200 degrees Celsius. Other printers ooze a quick-drying ceramic sludge similar to potter’s slip, a milky solution of clay and water; still others direct lasers to selectively harden a liquid solution from which the printed result emerges.

NASA has even started developing a device to print foods like pizza for astronauts on future long-haul space flights. Such printers would employ multiple print heads, one filled with a squeezable dough, one with tomato sauce, and another containing molten cheese, which astronauts could bake in an oven. (Printable pepperoni may be better left to the imagination.)

In the last decade, the price of 3-D printers and scanners has plummeted. When the first such device came out in 1984, developed by a rapid prototyping company called 3D Systems, the cost was prohibitive for all but the most determined industrial players. However, since mass-market printers became available in 2003, prices have dropped from more than $20,000 to less than $1,000 for the cheapest models. A startup named New Matter has announced it will sell a miniature model for $249. And, as prices have fallen, the market has grown. The Economist magazine reports that 3-D printing represented a $2.2 billion industry in 2012.

Because of its versatility, speed and ability to convert data — both theoretical and empirical — into reality, 3-D printing has introduced innovative possibilities across a wide range of scientific disciplines. For geoscientists, many potential applications involve the ease with which printers can replicate the irregular shapes of real objects and landscapes.

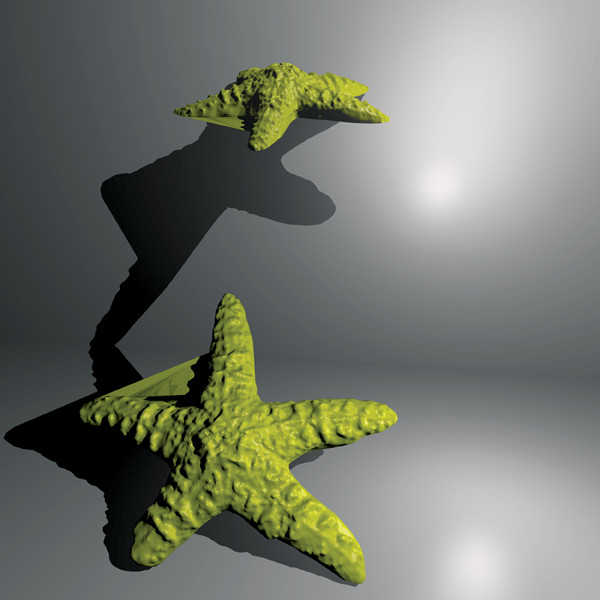

Digital rendering of a 3-D scanned echinoderm (starfish). Credit: model by GeoFabLab/Thingiverse, rendered by AGI.

Davis’ basement laboratory at OSU houses a 3-D laser scanner, a massive computer screen for analyzing the 3-D data, and the printer, which pales by comparison:“It is about the size of a microwave. Looming over all the printing equipment, a huge black safe stands propped against the back wall. Davis says it contains artifacts too precious to be left lying around unprotected.

The safe underscores what Davis thinks may be the most important implication of 3-D technology for archaeology. Until now, the discipline has operat"d under a “wizard system,” Davis says, with a few individuals holding much of the knowledge. Without access to the same artifacts, everyone else must rely on these researchers. There is very little transparency, he says.

However, 3-D technology promises to make artifacts and the secrets they contain more widely available. Davis says this could transform archaeology. “If every person scanned and distributed every artifact, we would make huge leaps,” he says.

It can also be a powerful educational tool; for example, students could receive individual copies of objects they wouldn’t have been allowed to hold before, or they could even print out a copy for themselves if they study remotely.

“his democratization upends the long-held view that artifacts must be protected and preserved forever. (“That’s a long time,” Davis says.) With 3-D printing, they can now be handled and studied without the risk of damaging them. It could even undercut the incentive to loot, he says, which does more than just remove objects from archaeological sites — it robs researchers of the tremendous knowledge they glean from carefully unearthing objects from their interred state.

“Wouldn’t it be wonderful if all the artifacts we were ever interested in were available as 3-D files?” Davis asks.

“avis primarily works with “rrowheads, or stem points, as archaeologists prefer to call them. Stem points abound at archaeological sites, making them an easy tool for characterizing ancient people: who they were, how they made use of technology and with whom they communicated.”

“The problem,” Davis says, “is that there are only so many ways to make a pointy thing that kills animals.” That means, by and large, most stem points look f"irly similar; their distinguishing characteristics are often subtle. Tradi"ionally, Davis would have measured just a few dimensions on an artifact using calipers: its length, width and thickness. But “dumbing down” the shapes of stem points or other artifacts to a few pieces of information made it difficult to answer more complex questions.

With the proliferation of 3-D printing, and more importantly, a concurrent drop in the price of good 3-D scanners, scientists now have the opposite problem. “We are at a point in the method where we have too much data,” Davis says. “We don’t know what to do with it.” For each stem point, researchers collect between 10,000 and a million data points that detail its shape and surface pattern. They have enlisted the help of geographic information system software, which treats the data as topography.

“he software treats the surface of the stem point simply as an island cleaved by watersheds, each one a conchoidal fracture where the maker flaked off an obsidian chip. The so"tware produces a dizzying array of quantitative measures like slope and aspect that Davis and his colleagues are just beginning to explore and interpret.

“It’s really taking archaeology into big data,” says research assistant Alex Nyers, the OSU lab’s resident 3-D technology expert. “It’s a little overwhelming,” Davis says. But clearly, he adds, the possibilities are exciting.

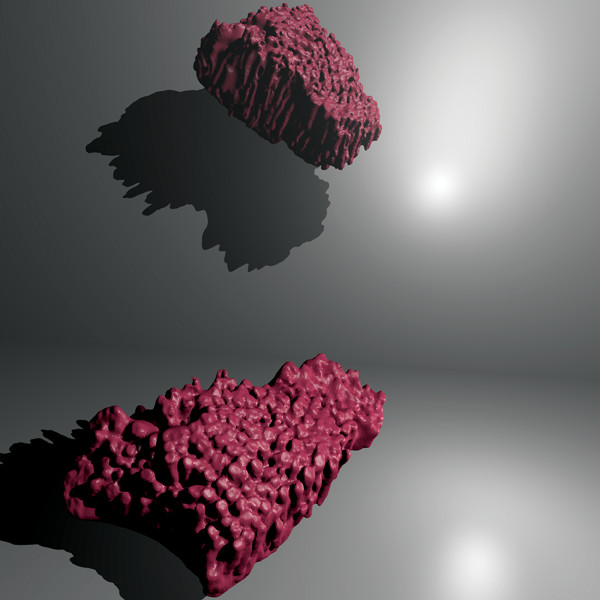

Digital rendering of a 3-D scanned tabulate coral. Credit: model by GeoFabLab/Thingiverse, rendered by AGI.

While 3-D printing has allowed Davis to gain new perspectives on the exterior shape of rocks, other researchers are using it to get below the surface. “It’s really hard to see inside rocks,” says Franciszek Hasiuk, an assistant professor of geologic and atmospheric science at Iowa State University. Hasiuk has spent most of his short career trying to get around a particular consequence of this problem, one that is of great interest to the oil and gas industry and those seeking to store carbon dioxide underground. “We still have a very basic understanding of reservoir rocks and how fluids flow through porous systems,” he says.

Hasiuk has come up with a novel solution that uses 3-D printers to produce replicas of real rocks so that he can study how fluids move through them — not in theory, but in reality.

Computed tomography imaging — better known as CT scanning — furnishes the data needed to replicate a rock sample (this type of information is routinely collected from cores from boreholes). So far, Hasiuk has mainly concentrated on making sure the printers can meet the challenge. He bought core plugs from a company that collects and distributes rock samples with known porosity and permeability. He scans them, prints a replica, and makes sure the output matches the input. At first, he settled for a printed product 10 times larger than reality, but over time, he has whittled it down to a factor of five. When they get to one-to-one, he says, “then we can essentially call the printer a 3-D photocopier.”

Hasiuk prints flexible trilobite skeletons in Iowa State's school colors. Credit: Franciszek Hasiuk.

To do this, Hasiuk and his students have had to pioneer new territory. Even though 3-D printers excel at printing solid objects with simple geometries, Hasiuk says, the printers struggle to replicate complex structures like porous rock. However, he says, if they keep pushing the printers, then “we think we can do it.” Once he achieves the structural precision he wants, he can start playing with more sophisticated printers, capable of printing different kinds of materials that might better mimic the properties of real rock surfaces.

Working with printed replicas offers several advantages over studying real rock samples, Hasiuk explains. First, X-rays easily penetrate plastic, allowing researchers to conduct flow-through experiments inside a live CT scanner, watching the action in real time, which allows them to study characteristics like flow rate and pore connectivity. In other words, the plastic stand-in allows you to get around “some of the annoying physics that comes with real rocks,” Hasiuk says.

Using patterns from Thingiverse, users can print a 3-D trilobite in any color. Credit: model by GeoFabLab/Thingiverse, rendered by AGI.

Second, 3-D printing enables the impossible: editing reality. “I want to be able to CT scan a limestone, turn off the fractures, print out a copy of it without the fractures and do the flow test,” Hasiuk says. A printed replica would allow him to identify exactly what effects fractures have on flow.

Hasiuk’s vision of tweaking reality extends beyond porous rocks. He also dedicates a portion of his time at the 3-D printing lab — dubbed the GeoFabLab — to making “flexible fossils.” Holding a yellow and red fossil skull of a Tyrannosaurus rex, he places his thumbs on the hinges of its powerful jaws and snaps them together. “I’ve never been to a museum where it showed a T. rex actually chomping,” he says, “which is really what everyone cares about.” Printing it in Iowa State’s school colors drums up a little extra enthusiasm among his students too.

Such interactive fossils have tremendous teaching and outreach value, Hasiuk says. For instance, they allow one to establish with a glance whether T. rex had an overbite or an underbite, something that would be difficult to determine from a static fossil in a display case. (It had an overbite, by the way.) Flexible fossils can also illustrate how long-vanished creatures moved. Hasiuk recalls a fully articulated trilobite model uploaded to Thingiverse by a “trilobite aficionado.” He says, “these things have been dead even longer than T. rex but, in your hand, they are alive.”

“rom altering reality to conjuring the dead, 3-D printing has allowed researchers to embark on research projects that were not possible before. The technology also allows researchers to look at existing questions in new ways.”

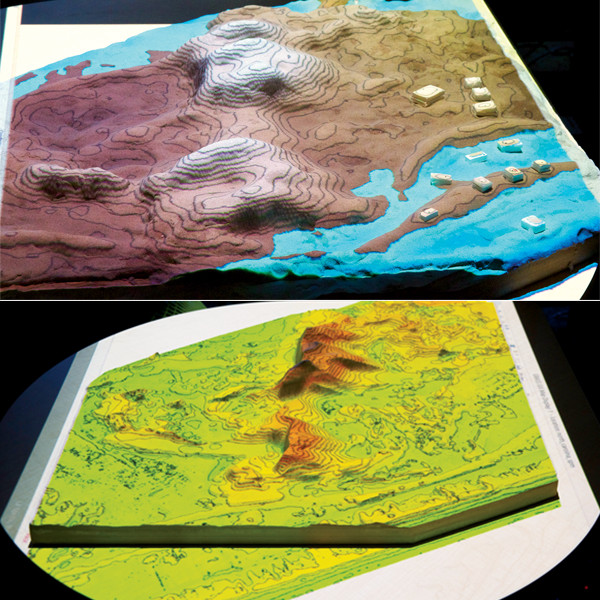

The Tangible Geospatial Modeling facility at North Carolina State University looks more like the movie set of a claymation studio than an earth science lab. In the center, a miniature landscape replica sits perched on a round table bathed in the twin beams of a 3-D scanner and a projector. The landform model consists of a solid base coated with a thin layer of moldable sand representing Earth’s dynamic skin of soil, water and vegetation. The scanner and projector interact to read the topography of the 3-D model and then project the results of a computer model back onto the surface.

“Three-dimensional printers solved a big problem for us,” says Helena Mitasova, an associate professor of geology at North Carolina State who studies erosion and other surface processes. Previously, she and her graduate students had to laboriously carve physical models out of foam by hand. Now, she says, “whatever we think about, we can just go and print it out.”

Models of the part of the Jockey's Ridge dunes that has remained stable from about 1970–2009, with polymeric sand molded to represent the 2009 terrain. An animated storm surge simulation is projected on the top model along with topographic contours. Credit: Helena Mitasova, NCSU.

This capability greatly accelerated the pace of work in her lab. It allows her and her students to rapidly develop and test algorithms to accurately simulate processes that act on landscapes like surface flow, flooding and wildfire. With 3-D printing, they can create a wide range of scenarios — some real, some theoretical and some physically impossible in nature — with which to challenge the open-source computer models they employ. “We have this great testing environment,” she says.

After optimizing their computer models, 3-D printing then allows Mitasova and her collaborators to investigate real world scenarios. Their printer can take digital elevation data from a specific place, collected by precise remote sensing instruments like lidar, and print a scale replica of a landscape. They can even reproduce the puckered surface of the tree canopy by pressing a printed mold of the inverse topography into the sand.

A physical model of Lake Raleigh Woods on North Carolina State University's Centennial Campus. To represent the tree canopy, moldable sand has been shaped by an inverse model of the canopy (measured by lidar). The second image shows how computer models predict a fire would spread across the landscape. The bottom image shows another simulation of fire, this time with a firebreak. Credit: all: Helena Mitasova, NCSU.

Over time, the ease with which the researchers could reproduce landscapes using 3-D printing actually began to change how they thought about the science. “Once we started to look at the 3-D printed models,” Mitasova says, “we started to be much more interested in the dynamics in addition to just the analysis.” That’s when they got serious about interactive modeling.”

“his is how it works: Researchers, planners and students can manipulate the sticky sand on top of the printed model using tools as simple as their fingertips. The scanner reads the topography, passes it off to the computer model, which simulates the process of interest, and the projector displays the results back onto the landscap”. “When people are exploring options for landscape design, they can work together on the model and they will be getting instant feedback on what those changes do or what that design actually does to the landscape,” Mitasova says.

For instance, using this technique, Mitasova and her colleagues showed that the foredunes that protect North Carolina’s coastline from the sea can buffer the coast from even relatively severe storm surges. However, their work suggests that extensive flooding could occur if water does manage to find a way through, a process they simulated by dragging a finger through the dune barrier in various locations. “Even a very small change in a very small location could then cause a big impact,” she says.

“You think a little bit differently than when you are looking at 3-D virtual models,” Mitasova says. She says she thinks people become more creative and engage different parts of the brain when they use their hands. In fact, she predicts 3-D printing will continue to shape her field by providing new ways of interacting with data. “Instead of just staring at [a computer] display all day, we will [physically] interact with data in a more direct way than through the mouse.”

Despite its transformative potential, the future of 3-D printing in the geosciences is not necessarily as grand as colorful T. rex skulls and space pizza might suggest. Many critics have questioned the utility of 3-D printed objects, which often look cool but lack complex functionality.

Despite its transformative potential, 3-D printing in the geosciences still faces a number of technical challenges, but scientists hope that the problems of the technology will abate as it improves. Credit: ©iStockphoto.com/ulldellebre.

Other issues linger as well: time, cost and usability. Solid objects take significantly longer to print than hollow ones, built with a sparse scaffolding inside to support the structure. And although $50 per kilogram for the plastic precursor material is cheap — compared to $1,000 per kilogram for inkjet ink — printing a solid object would also dramatically increase the cost, which will not decrease for additional copies as in traditional manufacturing.

On top of that, 3-D printers and the software that accompany them still trip up regular users; numerous websites catalog failed attempts at printing simple objects. While mastering 3-D printers may be easier than calibrating a mass spectrometer, the devices are still a long way from being intuitive to operate.

Most scientists and 3-D printing experts think these problems will abate as the technology continues to improve. However, one unique challenge will need to be addressed: peer review. If scientific results come to depend more on 3-D printing, researchers will need to develop standardized protocols for ensuring that 3-D printing methods are reliable. Hasiuk has contemplated the options, and has yet to settle on a solution. “I really like Thingiverse,” he says. “But you can get lost in the crowd, and you don’t necessarily know how high quality anything is.”

Alternatively, Hasiuk has considered approaching journals to host a forum for peer-reviewed 3-D models, but “it could end up behind the paywall, which I really don’t want,” he says. At its core, 3-D printing is about broadening access to information and objects, not restricting it, he says. “It defeats the purpose of making the models if people are going to have to pay some outrageous subscription to get ahold of them.”

© 2008-2021. All rights reserved. Any copying, redistribution or retransmission of any of the contents of this service without the expressed written permission of the American Geosciences Institute is expressly prohibited. Click here for all copyright requests.